Description

Flour Mill Commercial Machine 6FW-P12AB

Flour mill commercial machine 6FW-P12AB realizes full automation to enable all grains to be milled and cycled automatically to reduce labor. Adopts whole wind transmission, which reduces flour humidity. So far, this mini flour milling plant which features least investment, high automation, least labor cost (one person only required), least power consumption, least installed capacity, least requirement for workshop. Please know more at below:

Flour Mill Commercial Machine Main Details

6FW-P12AB FLOUR MILL MACHINE

Technological flow :Raw material cleaning – wetting – clean grain transmission – clean grain elevation – peeling – clean peeled corn elevation – flour milling – bagging

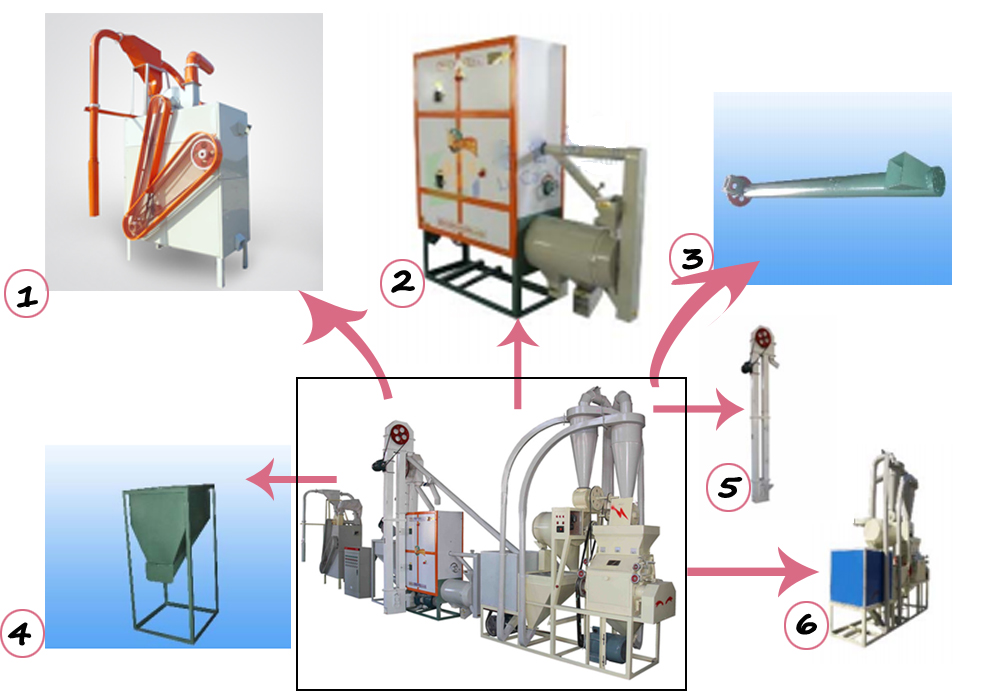

Mini flour milling plant

- (1) Cleaning machine: Take in material automatically, wind selection, remove stone, remove iron or metal, and remove big, medium, small and minor dusts. It’s a multi-functional machine also can peel beans skin and rice hull.

- (2) Flour milling machine: Fully automatic, produce super fine flour above 100 mesh. Machine runs at low temperature, suitable for grinding high quality of corn flour and soya bean flour. Fully closed during flour grinding, low dust density, easy to be cleaned, fit for national food safety standard.

- (3) Peeling and grits milling machine: Dry way peeling, remove skin, root, hilum very clean. And machine can be adjusted to control how clean you want depending on customer’s different requirement.

Flour Mill Commercial Machine Main Parameters

| Model | 6FW-P12AB | Net weight | 1970 KG |

| Raw material | Corn, wheat, rice and so on | Dimension | 8000 *1500*3000mm |

| Production capacity | 12ton/day | Warranty | 1 year |

| Motor power | 43.1kw | Quality | High Equipment |

Final Products of Flour Mill Commercial Machine

Excellent Efficiency

- This line begins with raw material auto feeding, remove big, medium, and small dust, remove stone, remove sand, remove dead seeds. Then wet the seeds, clean grains transmission, grain wetting, clean grains elevation, peeling, de-germ, remove root and hilum, peeled corn elevation till final flour milling.

Multifunction and 22 Different Sizes Grits

- Small-scale grain flour production line with the widest production range (coarse flour, fine flour, various grains and related granular chemicals, Chinese herbal medicine). Can produce 22 sizes of maize grits.

Working Video For Flour Mill Commercial Machine

- This video is about processing corn. We are showing our equipment for customers who visit our factory.

- We provide on-site or remote real-time testing services at any time.

Machines For Other Processing

Maize Peeling Machine

Process to peel off corn skins, germs, root, hiliums and others for better quality corn grits and flour. Peeling multiple grains.

Cleaning Machine

Is a combined automatic running machine to remove leaves, corn cobs, soils, stones pieces and other impurities from the corn seeds.

Flour Mill Machine

Process to mill the peeled corn into very fine flours for human consumption or crush whole corn into corn meal for food or animal feed.

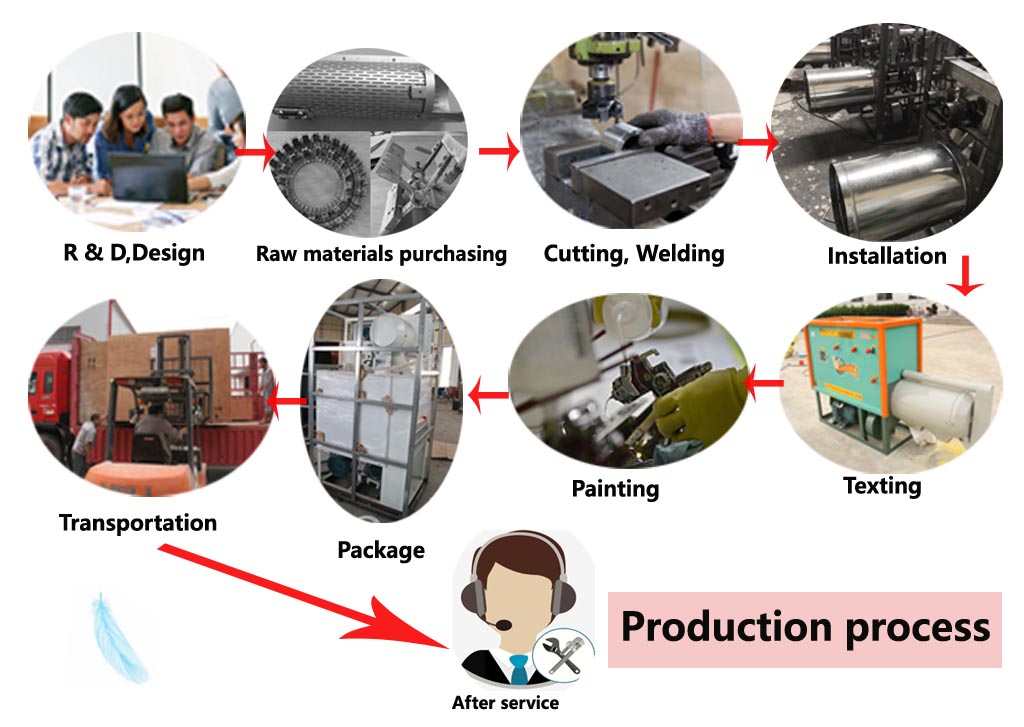

Machine Producing Process

We have a complete production process.

- All equipment Comply with ISO9001.

- Standardized production.

- Every machine tested strictly before delivery.

- Advanced design. High grade steel materials.

- Standard produce process, Skilled workers, Strict test before shipping.

- Professional service: Product use,Installation and operation guidance, machine maintenance.